Revolutionizing Manufacturing: The Benefits of Additive Manufacturing for Bridging Production.

In today's fast-paced manufacturing landscape, Additive Manufacturing (AM), commonly known as 3D printing, is emerging as a crucial tool for bridging production gaps. Once considered a futuristic novelty, this technology has now matured into a transformative force, offering significant advantages in reducing lead times, cutting costs, and enhancing operational flexibility. Endeavour 3D, a leader in the AM industry, underscores the profound benefits of this technology for bridging production in various sectors.

Accelerating Time-to-Market

One of the primary advantages of Additive Manufacturing is its ability to significantly accelerate time-to-market for new products. Traditional manufacturing methods involve lengthy and intricate processes to create molds, tools, and prototypes. In contrast, AM enables rapid prototyping, facilitating swift iteration and testing of designs. This agility allows companies to respond quickly to market demands and consumer feedback, a critical factor in industries such as automotive and consumer electronics.

Enhancing Cost Efficiency and Reducing Waste

AM offers notable cost efficiencies, particularly for low-volume production. Conventional manufacturing processes can be prohibitively expensive for small runs due to high setup costs and material waste. AM, however, builds products layer by layer, minimizing waste and optimizing material usage. This efficiency translates to lower production costs, making AM an economically viable option for bridging production until full-scale manufacturing is achieved.

Offering Customisation and Flexibility

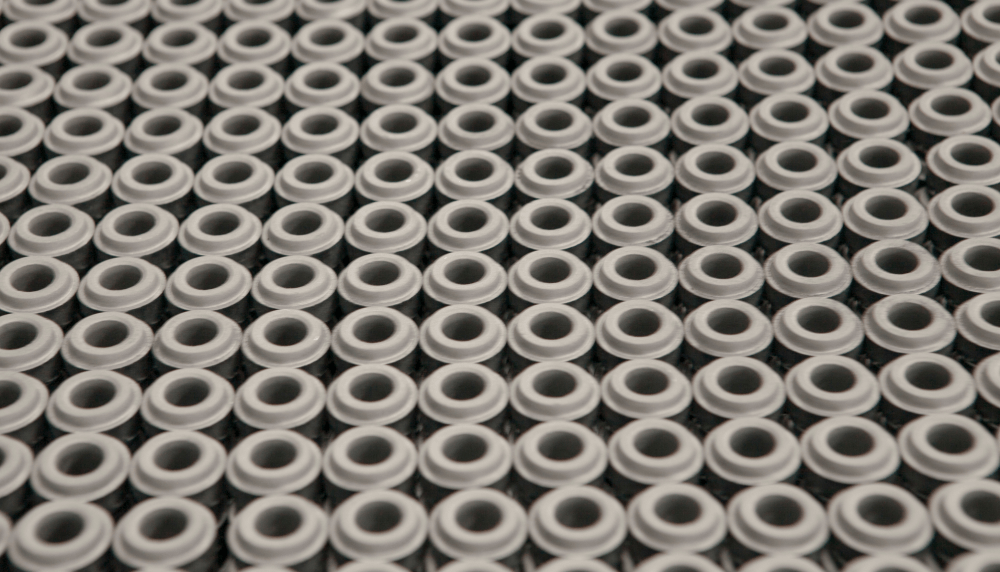

The flexibility of Additive Manufacturing is unparalleled. It enables high levels of Customisation without incurring significant additional costs. This capability is especially beneficial for industries that require bespoke parts or products tailored to specific needs. For instance, the medical field leverages AM to produce custom prosthetics and implants, while the aerospace industry uses it to create lightweight, complex components that would be impossible to manufacture using traditional methods.

Strengthening Supply Chain Resilience

AM also enhances supply chain resilience. Traditional supply chains are often vulnerable to disruptions from geopolitical issues, natural disasters, or pandemics. By integrating AM into their production strategies, companies can localize production and reduce reliance on distant suppliers. This decentralization leads to more resilient and responsive supply chains, mitigating risks and ensuring continuous production.

Promoting Environmental Sustainability

Sustainability is a growing concern for manufacturers. AM contributes positively to environmental goals by reducing material waste and energy consumption compared to traditional manufacturing methods. Additionally, by enabling localized production, AM can significantly cut down on transportation emissions. Companies adopting AM enhance their operational efficiency while contributing to broader environmental sustainability efforts.

Bridging Production Gaps

Bridging production gaps is a critical benefit of AM, particularly during the transition from prototype to full-scale production. AM allows companies to maintain momentum and continue generating revenue while scaling up their manufacturing processes. This capability ensures there are no significant disruptions or delays in getting products to market, maintaining a competitive edge.

Conclusion

Endeavour 3D's expertise in Additive Manufacturing is driving a paradigm shift in how products are designed, developed, and brought to market. The benefits of AM in bridging production are profound, offering speed, cost savings, flexibility, supply chain resilience, and sustainability. As this technology continues to evolve, its integration into mainstream manufacturing is expected to become even more widespread, heralding a new era of efficiency and innovation in production processes. For manufacturers aiming to stay ahead of the curve, embracing Additive Manufacturing is not just an option; it is a necessity. Endeavour 3D's pioneering efforts are a testament to the transformative potential of this technology in bridging the gap between concept and reality.