Selective Laser Sintering (SLS) is an advanced additive manufacturing technology that uses a high-powered laser to fuse polymer powder particles into a solid structure.

Stereolithography (SLA) is an advanced additive manufacturing technology that uses a UV laser to cure liquid photopolymer resin into solid structures.

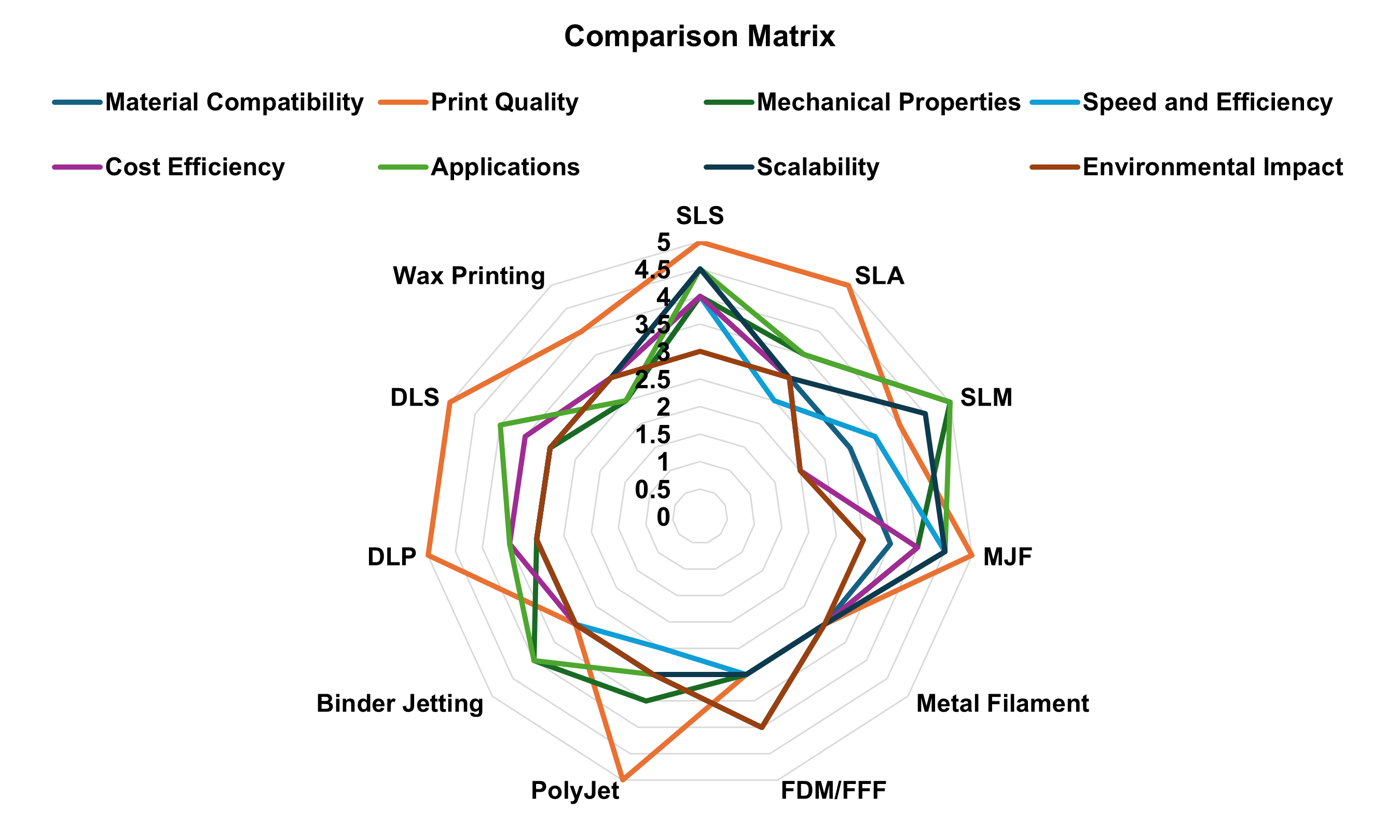

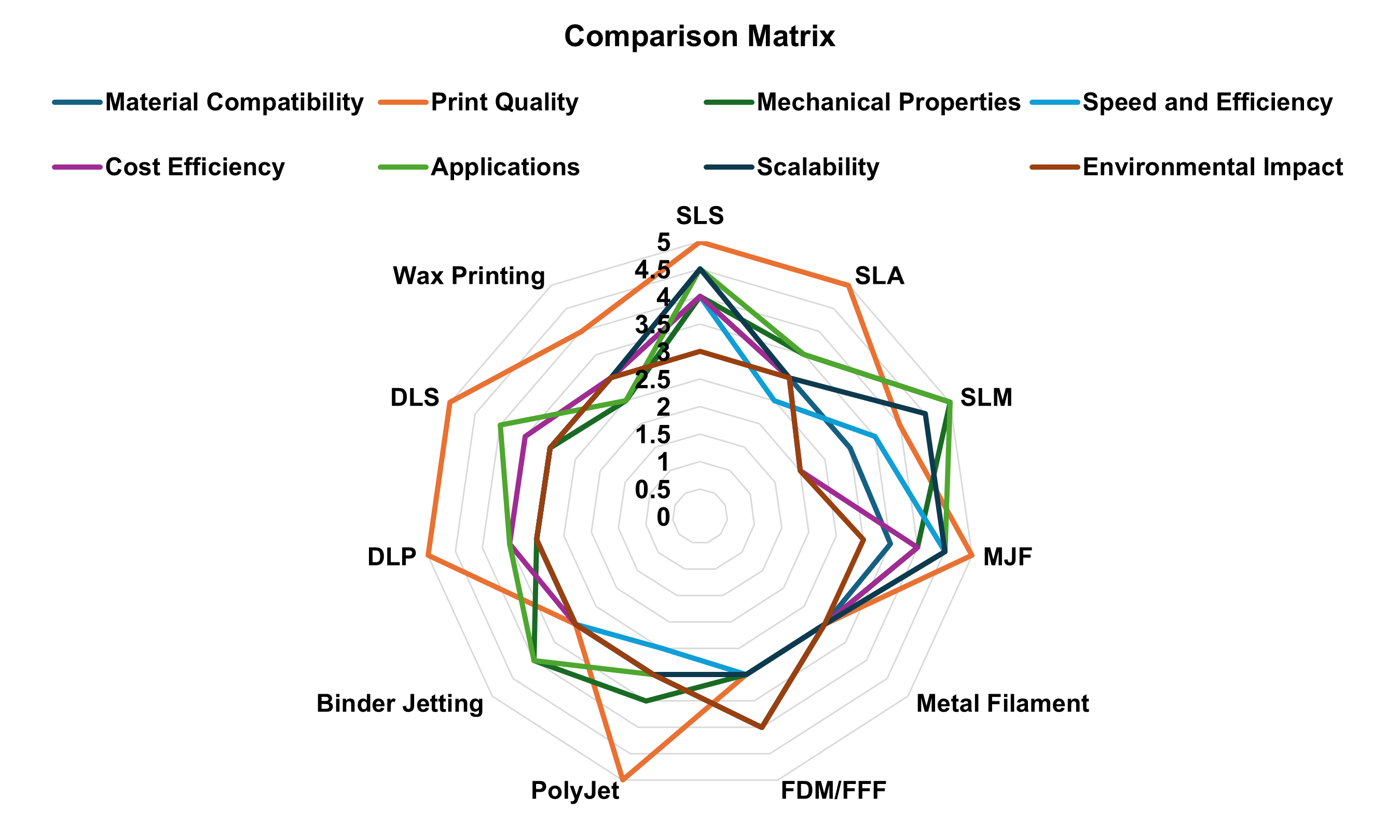

| Technology | Material Compatibility | Print Quality | Mechanical Properties | Cost | Applications | Scalability | Environmental Impact | Additional Information |

|---|---|---|---|---|---|---|---|---|

| SLS | Polymers, composites, some metals | Good surface finish, high dimensional accuracy, medium layer resolution | High strength, moderate durability, moderate flexibility | Medium setup cost, high per part cost, high maintenance cost | Prototyping, functional parts, aerospace, medical | Medium to large build volume, suitable for small to medium batches | Medium waste, high energy consumption, moderate recyclability | Powder-based process, good for complex geometries |

| SLA | Photopolymers | Excellent surface finish, high dimensional accuracy, high layer resolution | Moderate strength, brittle, low flexibility | High setup cost, low per part cost, low maintenance cost | Prototyping, dental, models, jewelry, high-detail models | Small to medium build volume, suitable for small batches | Low waste, moderate energy consumption, low recyclability | Highly detailed prints, smooth surface finishes |

| SLM | Metals | Good surface finish, high dimensional accuracy, medium layer resolution | Very high strength, excellent durability, low flexibility | High setup cost, high per part cost, high maintenance cost | Aerospace, medical implants, industrial tooling | Medium build volume, suitable for small batches | High energy consumption, low recyclability | Ideal for high-strength metal parts |

| MJF | Polymers | Good surface finish, medium dimensional accuracy, medium layer resolution | High strength, good durability, moderate flexibility | Medium setup cost, medium per part cost, moderate maintenance cost | Functional prototypes, small production runs, end-use parts | Medium build volume, suitable for medium to large batches | Moderate waste, moderate energy consumption, moderate recyclability | Fast printing, good for functional parts |

| Metal Filament | Metal-filled polymers | Moderate surface finish, medium dimensional accuracy, medium layer resolution | Moderate strength, good durability, moderate flexibility | Moderate setup cost, medium per part cost, moderate maintenance cost | Prototyping, functional parts, hobbyist applications | Medium build volume, suitable for medium batches | Moderate waste, moderate energy consumption, moderate recyclability | Combines FDM with metal properties |

| FDM | Polymers, composites | Good surface finish, low dimensional accuracy, low layer resolution | Moderate strength, good durability, moderate flexibility | Low setup cost, low per part cost, low maintenance cost | Prototyping, hobbyist projects, functional parts | Medium to large build volume, suitable for mass production | Low waste, low energy consumption, high recyclability | Widely accessible, versatile material options |

| PolyJet | Photopolymers, elastomers | Excellent surface finish, high dimensional accuracy, high layer resolution | Moderate strength, moderate durability, high flexibility | High setup cost, medium per part cost, high maintenance cost | Prototyping, medical models, high-detail parts | Small to medium build volume, suitable for small batches | Moderate waste, high energy consumption, moderate recyclability | Multi-material and color printing capabilities |

| Binder Jetting | Metals, ceramics, sand | Good surface finish, high dimensional accuracy, medium layer resolution | Moderate strength, good durability, low flexibility | High setup cost, moderate per part cost, high maintenance cost | Prototyping, castings, full-color parts | Large build volume, suitable for medium to large batches | Moderate waste, high energy consumption, moderate recyclability | Suitable for large and complex parts |

| DLP | Photopolymers | Excellent surface finish, high dimensional accuracy, high layer resolution | Moderate strength, brittle, low flexibility | High setup cost, moderate per part cost, high maintenance cost | Prototyping, dental, small to medium parts | Small to medium build volume, suitable for small batches | Low waste, low energy consumption, low recyclability | Similar to SLA, but uses a projector for curing |

| DLS | Photopolymers, elastomers | Excellent surface finish, high dimensional accuracy, high layer resolution | High strength, good durability, high flexibility | High speed, moderate per part cost, moderate maintenance cost | Prototyping, medical models, large-scale production | Medium build volume, suitable for mass production | Moderate waste, high energy consumption, moderate recyclability | Continuous liquid interface production (CLIP) |

| Wax Printing | Wax | Good surface finish, low dimensional accuracy, medium layer resolution | Low strength, low durability, high flexibility | Moderate setup cost, moderate per part cost, minimal maintenance cost | Prototyping, small precision casting | Small to medium build volume, suitable for small batches | Low waste, moderate energy consumption, moderate recyclability | Specialised for detailed casting molds |

At DustForge, we believe that innovation is the key to progress. We provide cutting-edge technological solutions to help your business break boundaries and unlock the potential of the future. Whether you're looking for powerful tools to propel your projects or require customised services to meet specific needs, DustForge has you covered.